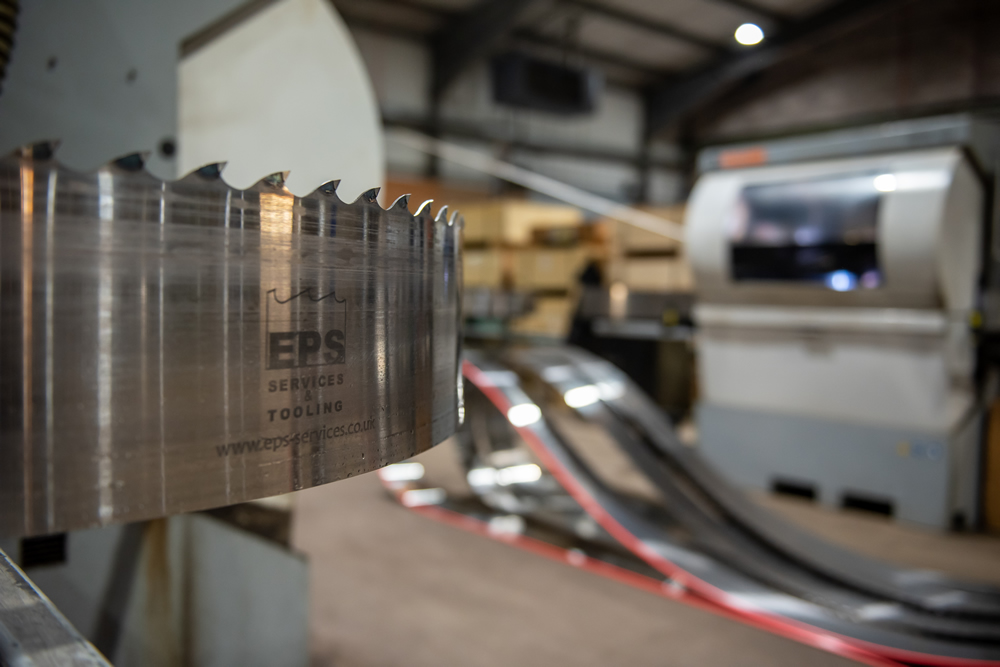

Wide Bandsaws

Wood band saw steel is characterised by high fatigue strength, good elasticity and excellent benchabillity, allowing for the production of high-quality blades with long run-times.

UK Supply

BOHLERSRIP is supplied to EPS directly by (Bohler Uddeholm precision strip) Voestalpine in Austria and is respected as the best quality precision strip coil to support the timber cutting industry in the world.

EPS hold a stock of over 40 tons of steel to support our customer’s immediate bandsaw requirements to ensure we can promptly supply the majority of orders.

We can manufacture wide band saws in a range from 60mm to 311mm wide with the blades tensioned to your specifications. Your band saws can be supplied ready to run or just toothed and joined. The teeth can be set straight or in a vari-pitch format. The cutting teeth can be Swaged and Shaped, or Stellite Tipped for a more durable and longer lasting cutting edge. All these processes are performed in house to ensure we can offer our customers the best possible quality.

View more about our Wide Bandsaw Blades

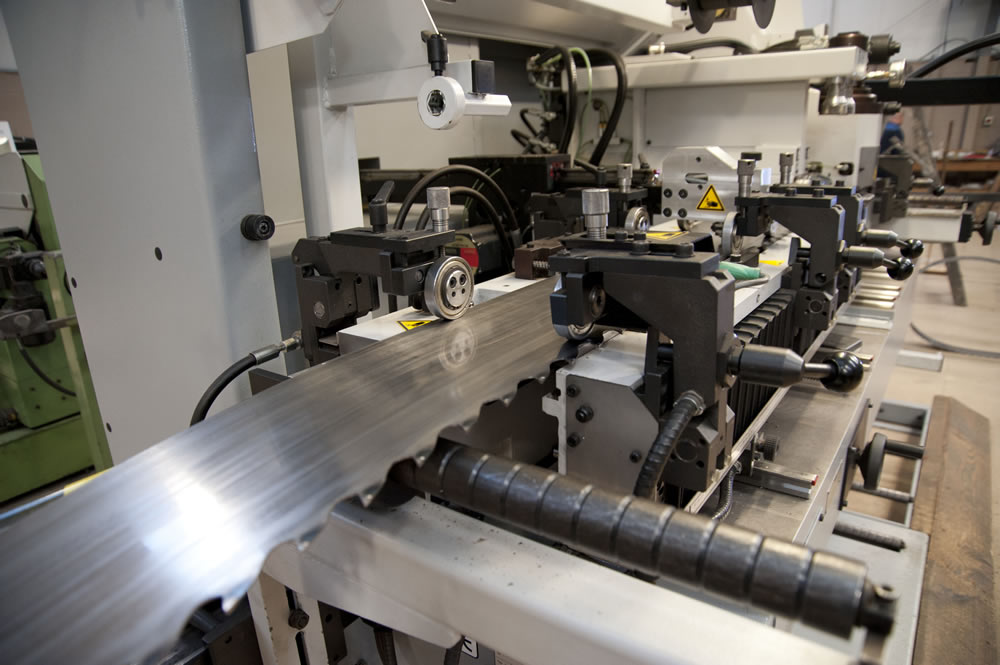

Our modern press lines produce toothed steel to exacting tolerances while we can punch in a variety of different tooth shapes to match customer requirements. We Butt Weld all our band saws to ensure inclusion free joining and tempering within a very small heat zone.

Our triple plasma-arc manufacturing lines provide high quality Stellite tipping, whilst hydraulic automated swaging is used for non-tipped blades. Our fully automatic CNC hydraulic tensioning machinery is programmable to meet every blade application, whilst final tooth and side grinding is undertaken on one of our many Vollmer CNC wet grinding machines, which are capable of grinding up to 99 different tooth shapes, including a whole range of Vari-pitch formats.

Stellite Tipping

For extra tip hardness and improved length of service, for cutting frozen timber or for extra smooth finish on softwoods our sophisticated Plasma-arc Stellite tipping machinery will fuse a deposit of hard metal to Rockwell 44C, and correctly anneal it by induction loop heating. The teeth are then precision ground on water cooled CNC equipment to give accurate and razor sharp teeth.

Variable Pitch Teeth

We are also able to offer improved speed of cut and a decrease in blade resonance with the use of a varying pitch formatted teeth, with our unique CNC Production Centre. We can now create different pitch formats to meet your unique requirements.

Cutting Frozen Timber

To help cut frozen (or partly frozen) timber we can provide a frost notch to each saw tooth in a consistent format utilising our modern CNC machinery. A frost notch can help the bandsaw blade process the frozen sawdust more effectively this allowing the timber mill to maintain cutting speeds.