Green Steel

Green Steel Bandsaw Blades for Sustainable Cutting

As sustainability becomes a business imperative, the steel industry is embracing innovation—and green steel is leading the way. Manufactured using electric arc furnaces powered by renewable energy, green steel dramatically reduces carbon emissions compared to traditional methods. Now, this low-carbon breakthrough is transforming the bandsaw blade industry.

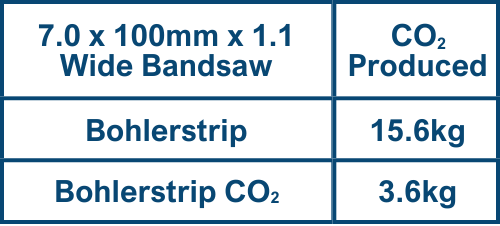

Voestalpine, the global pioneer in green steel bandsaw strip coil, produces high-performance steel under its premium Uddeholm and Böhler brands. As the exclusive UK supplier, EPS Services & Tooling Ltd brings these CBAM-compliant green steel bandsaw blades to manufacturers across the country—combining cutting-edge performance with a lighter environmental footprint.

What is Green Steel?

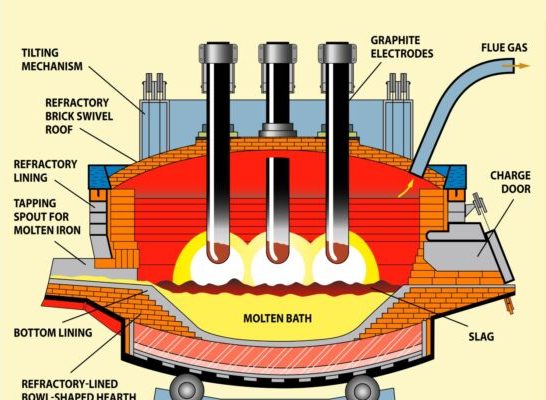

Green steel is steel made with a significantly reduced carbon footprint, typically through the use of electric arc furnaces powered by renewable energy instead of traditional coal-based methods. Voestalpine is leading the industry with its Uddeholm and Böhler brands, producing high-quality steel that meets demanding industrial standards—minus the excessive emissions. It’s the same strength and performance you expect, but with a far smaller environmental impact. It’s steel, just… greener.

|

|

| Blast furnace running on fossil fuels (source) | Electric arc furnace running on hydro-electric power (source) |

Application in Bandsaw Strip Coils

Bandsaw strip coils, essential for high-performance cutting applications, are now benefiting from the use of green steel. The shift to this more sustainable material means manufacturers—and by extension, their customers—can reduce their environmental footprint without compromising on blade quality or durability. At EPS, we’re proud to be at the forefront of this move, providing bandsaw blades that work hard and tread lightly.

EPS Services & Tooling Ltd: Leading the Green Initiative

With over 35 years of experience in manufacturing and servicing bandsaw blades, EPS is committed to combining performance with progress. Operating from four service centres in Wiveliscombe (Somerset), Kirkcaldy (Fife), Chelmsford (Essex), and Gerrymet in the West Midlands, we offer nationwide coverage and tailored solutions for timber processing operations of all sizes. Through our close partnership with Voestalpine, we supply BOHLERSTRIP and UDDEHOLM blades made from green steel—ensuring you get top-tier quality and sustainability in one package. For more details on how green steel fits into your operation, check out our FAQ section.

View our Frequently Asked Questions about Green Steel for more information