Thin Kerf Saw Blades: 5 Reasons to Switch & Save Energy

EPS Services & Tooling | October 2025

Discover how thin kerf saw blades help sawmills boost timber yield, reduce waste, and cut energy costs.

What Is a Thin Kerf Saw Blade?

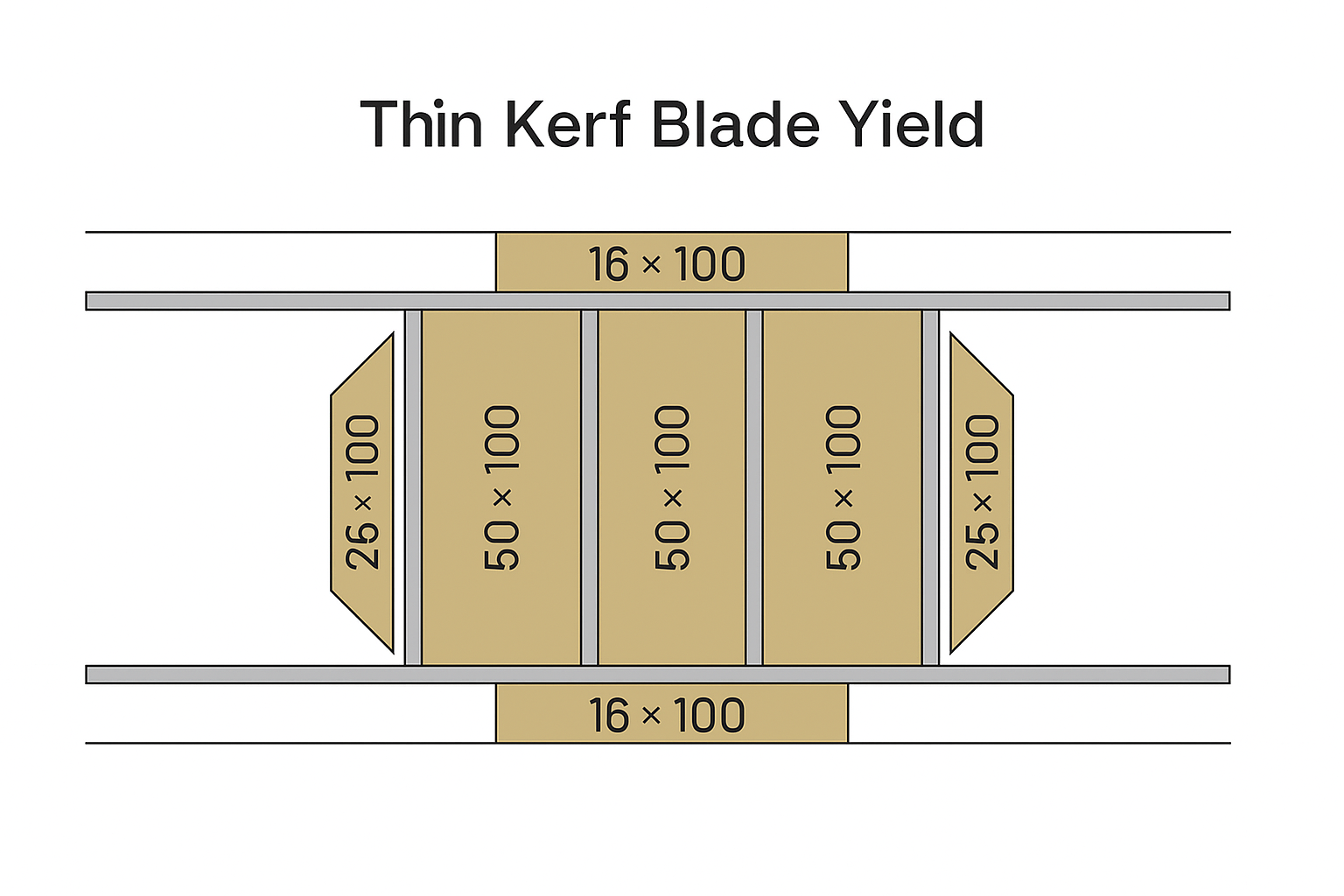

The “kerf” is the width of material removed by a saw blade during cutting. Thin kerf saw blades remove as little as 1.8 mm, compared to traditional 3.2 mm+ blades, dramatically increasing usable wood yield.

More Product, Less Waste

- Up to 25% more usable wood per log

- Less sawdust and material loss

- Improved conversion rate for premium timber

Maximising timber yield is essential, especially when log supply is limited or expensive. This also reduces your environmental impact.

Lower Power Consumption & Smoother Production

- Reduces cutting resistance and energy use

- Minimises wear on critical machinery

- Enables smoother, more stable sawmill operation

Why Thin Kerf Technology Is the Future of Sawmilling

As sustainability becomes non-negotiable, sawmills need to adopt leaner, more efficient systems. Thin kerf saw blades offer a reliable path to more output with less input — especially when paired with EPS’s expert consultation.

Learn more about our saw blade servicing options and how they complement thin kerf setups.

External Industry Resource

For further information on UK timber efficiency guidelines, read the UK Forestry Research Sawing Guidelines.

FAQs About Thin Kerf Saw Blades

How much more timber can I get from a thin kerf blade?

Up to 25% more usable wood, depending on blade setup and log quality.

Are thin kerf blades more fragile?

Not at all. EPS blades are engineered for both strength and precision in high-demand production environments.

Can thin kerf saw blades reduce my energy costs?

Yes — thinner blades cut more efficiently, using less power per pass.