Bandsaw Blade Tooth Pitch Explained:

Bandsaw Blade Tooth Pitch Explained: Why TPI Matters More Than You Think

When choosing a bandsaw blade, tooth pitch is often treated as a secondary detail. Many people focus first on blade width

or overall blade type, with TPI mentioned almost as an afterthought.

In practice, tooth pitch has a significant influence on how a blade behaves in the cut. It affects cutting speed, surface

finish, blade life, and even how hard the machine has to work. Issues that are often blamed on setup or machine condition

can frequently be traced back to blade selection.

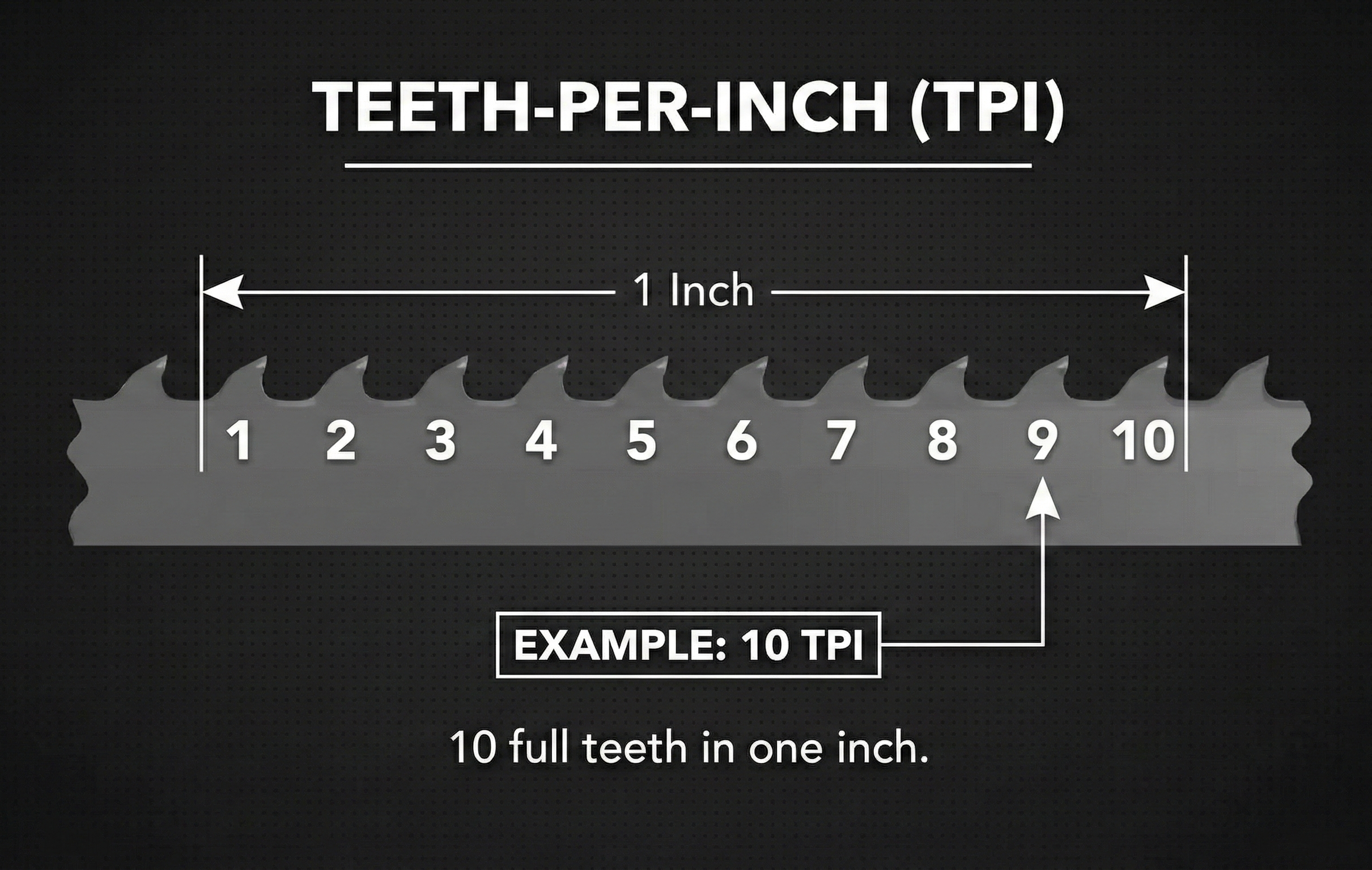

What does tooth pitch or TPI mean?

Tooth pitch is the number of teeth along one inch of the blade, usually written as TPI, meaning teeth per inch.

- A 3 TPI blade has three teeth in every inch

- A 10 TPI blade has ten teeth in every inch

Lower TPI blades have larger teeth with deeper gaps between them. Higher TPI blades have smaller teeth that are more

closely spaced. Those gaps are called gullets, and they carry chips away from the cut.

Why gullets are so important

Every tooth produces a chip as it cuts. If chips cannot clear efficiently, they pack into the gullets. Friction rises,

heat builds, and blade life drops. This is one of the most common reasons blades dull faster than expected.

Many cutting issues discussed in our guide to

fixing bandsaw cutting problems

can be linked back to poor chip clearance caused by incorrect tooth pitch.

Teeth in the cut and cutting stability

A useful rule of thumb is aiming for at least three teeth engaged in the material at all times.

This helps spread the cutting load and keeps the blade running smoothly.

Too few teeth in the cut can cause grabbing and chatter. Too many teeth can lead to rubbing rather than cutting, which

generates heat and reduces efficiency.

How incorrect tooth pitch shows up in real use

Fast dulling, slow cutting, burning, and wandering cuts are often linked to pitch selection, even when the machine setup

is otherwise sound. In some cases, these symptoms are mistaken for blade quality issues.

If you are already using thinner blades to improve yield, as discussed in our article on

thin kerf saw blades and timber yield,

selecting the correct tooth pitch becomes even more important.

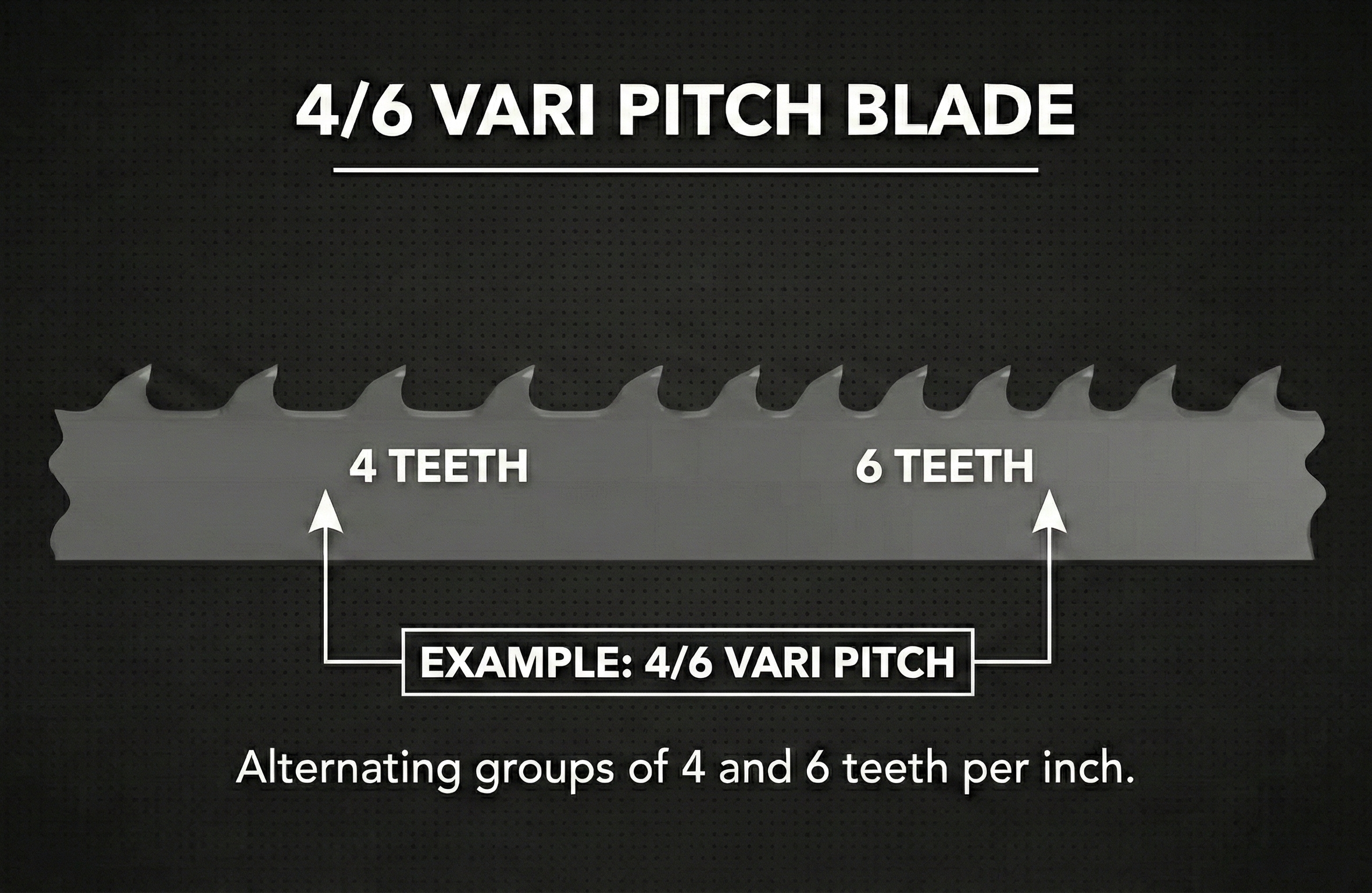

Variable pitch blades explained

Variable pitch blades change tooth spacing along the blade. The aim is to reduce vibration by preventing repeating

harmonic patterns during cutting.

They can run quieter and feel more stable, particularly in challenging materials, but they are not a substitute for

choosing the correct pitch range in the first place.

Final thoughts

Tooth pitch affects far more than surface finish. A small change in TPI can improve cutting performance, consistency,

and blade life. It is often one of the simplest adjustments to make when refining cut quality.

For a broader look at blade selection, you may also find our

bandsaw blade selection guide

useful.

Quick reference

TPI:

Teeth per inch, the number of teeth along one inch of blade.

Gullet:

The space between teeth that carries chips away from the cut.

Variable pitch:

Tooth spacing changes along the blade to help reduce vibration.

When troubleshooting cut quality, tooth pitch is often a good first check before adjusting guides or tension.