Sizing Up: How to Choose the Right Bandsaw Blade

Bandsaw Blade Guide: Understanding Blade Types and Specifications

In this comprehensive bandsaw blade guide, we’ll show you how to select the perfect blade for your machine—covering length, width, thickness, and TPI.

1. Blade Length

Ensuring the blade length is correct is essential for bandsaw safety and functionality. A blade that is too short simply won’t fit, while one that’s too long can lead to poor tension and wandering cuts. Check the manufacturer’s specifications or measure an existing correctly fitting blade to be certain.

Using the right length prevents unnecessary wear on the machine and the blade, improving cut quality and safety over time. If you’re uncertain, consult EPS Services for guidance.

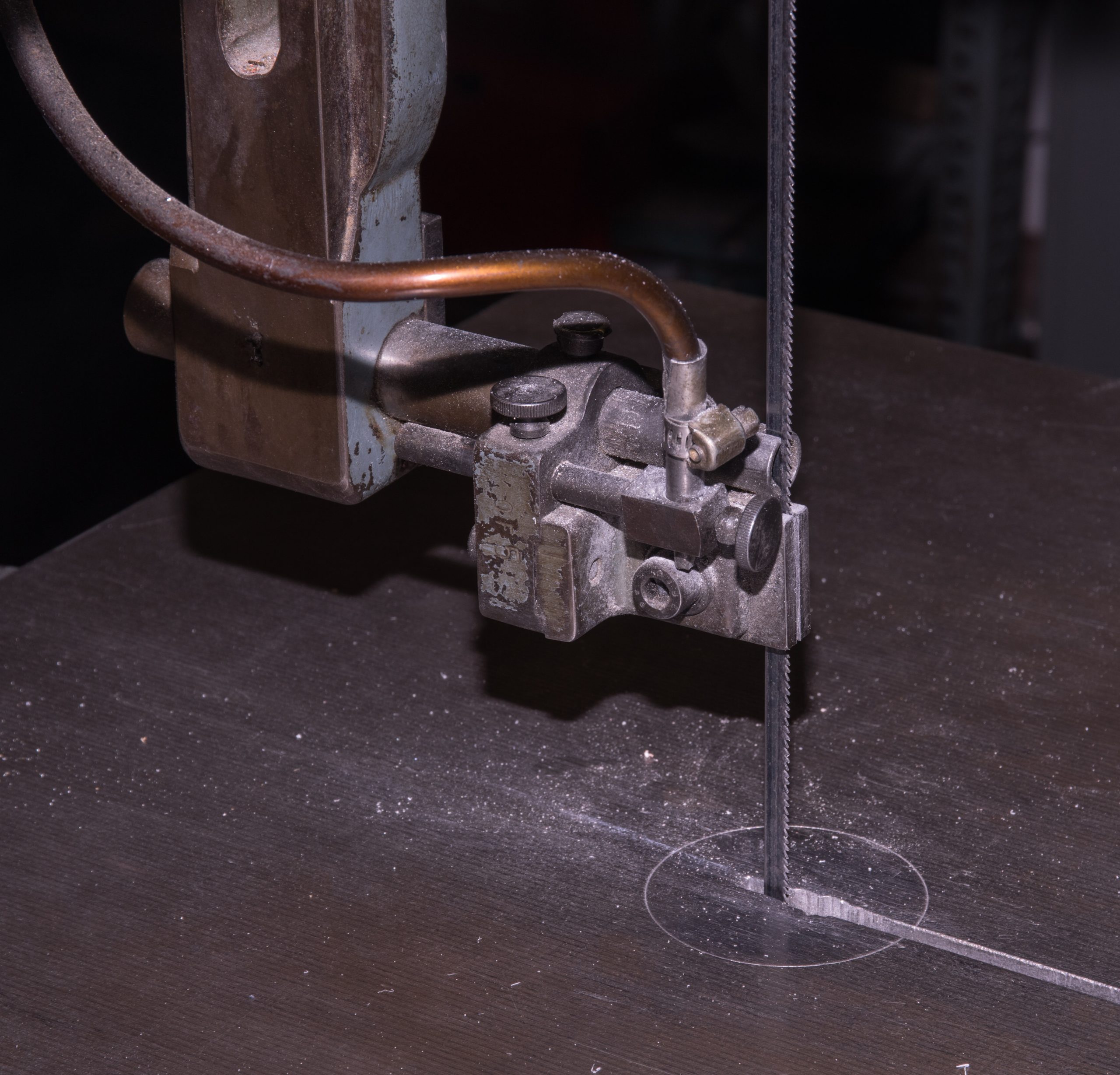

2. Blade Width

Blade width affects both the stability of straight cuts and the ability to make tight curves. Wider blades (¾″ or 1″) are great for straight resawing work, offering excellent rigidity. Narrower blades, such as ⅛″ or ¼″, are designed for intricate cutting and small-radius curves—perfect for scrollwork or detailed patterns.

A good workshop setup includes multiple blade widths, allowing for flexibility across different jobs and materials.

3. Teeth-Per-Inch (TPI)

The number of teeth per inch impacts cut finish and feed rate. Here’s how it breaks down:

- 2–3 TPI: Rough, aggressive cuts in thick wood

- 4 TPI: General-purpose cutting

- 6–8 TPI: Balanced cuts for most wood types

- 14 TPI: Smooth, slow cuts for finer results

- 18–32 TPI: Excellent for metals and thin materials

Lower TPI cuts faster but rougher, while higher TPI blades provide smoother results with slower feeds. Always choose based on the material and desired finish.

4. Blade Thickness

Blade thickness determines flexibility and resistance to stress. Thicker blades are more stable and durable, ideal for straight, powerful cuts. However, they require larger wheels to avoid cracking. Thin blades are better for small machines and curved cuts but can wear faster under heavy loads.

Here’s a quick guide to thickness and wheel compatibility:

| Wheel Diameter | Blade Thickness |

|---|---|

| 4″–6″ | .014″ |

| 8″–10″ | .020″ |

| 12″–18″ | .025″–.035″ |

| 30″+ | .042″+ |

Why It Matters

Incorrect blade thickness can lead to metal fatigue, breakage, or improper cuts. Ensuring your machine’s wheel size matches the blade is a key factor in safe, efficient operation. If in doubt, reach out to EPS for technical advice tailored to your machine setup.

When working with bandsaws, safety should always come first. In addition to choosing the right blade, it’s essential to follow best practices for machine use and maintenance. The Health and Safety Executive provides detailed guidance on safe use of bandsaws in woodworking environments, including guarding, tensioning, and operational checks. You can view their official advice in the HSE guide on safe blade use.

EPS Expertise

With so many variables—length, width, TPI, and thickness—selecting the right bandsaw blade can seem complex. That’s where EPS Services & Tooling comes in. Our experienced team is here to help you match the perfect blade to your machine and application. All of our high-quality bandsaw blades are manufactured in-house using premium carbon steel and precision welding techniques. Ready to buy? Visit our online shop to browse and order the full range of narrow band blades today.

With branches across Essex, Somerset, Fife, and the West Midlands, EPS is ready to support your cutting needs. Get in touch for tailored advice or explore our full blade guide online.

🔗 Read the full guide and download your handy wall chart here